… taught by Bob Hazeltine, legendary Master Bench Jeweler, and the former Department Director for the Gemological Institute of America's Jewelry Manufacturing Arts. Bob teaches silver- and gold-smithing, as well as classes on casting, wax carving, enameling, soldering and fabrication, stone setting methods, repousse, engraving and mold making. He works with both beginning and advanced students, and has recently mastered blowing glass. He teaches at the Santa Fe Jewelers Supply store, after giving up the Hazeltine School of Fine Jewelry to concentrate on glass-blowing.

Frank and I took jewelry making classes from several different silversmiths back in the 80s. We started in an evening program through Montgomery County Public Schools, and moved along to two or three other instructors. After acquiring all the basic equipment needed to pursue silversmithing as a hobby, we began having children. It was incredibly exciting to get back to the basics with a teacher as patient and interesting as Bob, especially after the sensory overload of silver jewelry that is Santa Fe.

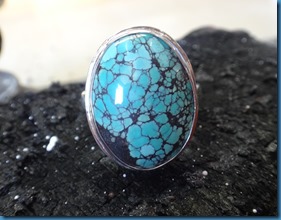

Between 9:30 and 4:00, with an hour and a half off for lunch, we each completed one ring, using a small butane torch. We learned so many techniques and tricks from Bob that our work will never be the same. Bob is a stickler for details, and carried the finishing touches far beyond anything anyone else had ever shown us.

Good father that he is, Frank’s ring (bottom) is for Mia.

We returned to the hotel to pack and get ready to leave beautiful Santa Fe. It has been an adventure to remember!

One of the memorable details is chile (the local spelling). Chile is served in every restaurant in the Santa Fe area. The customary question is, “Green or red? Or Christmas?” (A mix of green and red.) Our response is usually, “Which is hotter?” And surprisingly, the answer varies. But it is all hot by East Coast standards.

Almost every supermarket parking lot sports large propane tanks hooked to what looks like large barbecues or smokers. We were lucky one day to see what turned out to be a chile roaster in action. This is the prime season for chile roasting. People buy large burlap bags full of red, green or mixed chile peppers, then carry them out to the parking lot for roasting. The roaster dumps the bag into the cage, latches the door, and turns on the flame. It takes about 5 minutes to roast a batch, with the peppers popping and spitting seeds, while softening and browning. The roaster periodically spritzes the peppers with water during the roasting. (Some people are better roasters than others.) The roasted peppers are dumped into a plastic bag, and returned to the customer.

A customer filled us in on what happens next. He “sweats” the peppers by leaving them in the sealed plastic bag for a few hours. Then he drains any liquid, peels the outside skins, and places the peppers in batches in plastic bags in the freezer. The trick is to roast enough peppers to last until the next summer. Most people don’t make it, running out in January or March. It was local flavor we loved.